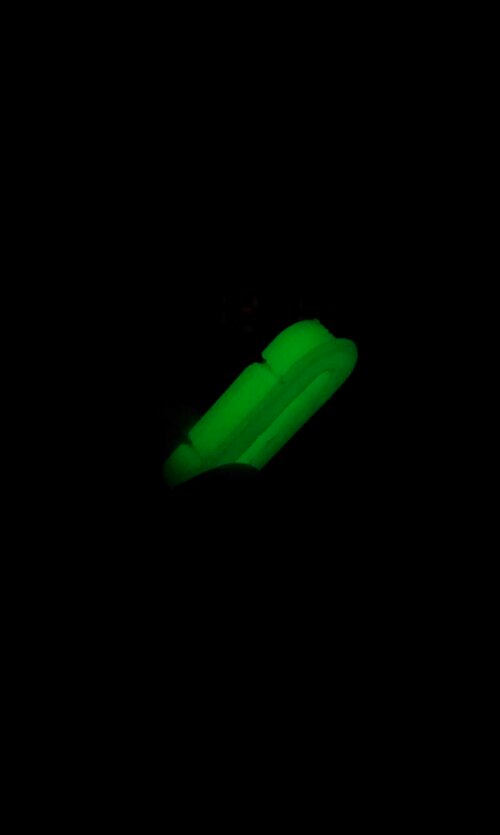

Testing new glow in the dark filament. A coin slot printed in 25 minutes glowing in night darkness

Category Archives: Reprap

PLA 1.75mm and 3mm samples for the store – evaluation

I have recently been in contact with a company regarding supplying 3D printer filament at great prices.

These filaments are available in several lovely colours including Black, White, Blue, Bubblegum Pink, Gow in dark, Yellow, Green, Jasmine Green, etc etc…

And, i am to become a supplier of their filaments!

Well, with a friend, we are teaming up to supply this great quality filament.

I am currently running through some sample ammounts of filaments currently printing in 1.75 mm, but 3mm will be available firstly.

I am also in development of a multiple bowden cable extruder, which will enable multi colour prints and support material in PVA, again available through this company! which we are going to be supplying.

Watch this space for more news!

Quadcopter 3D printed gimble with brushless motors

Something i have seen over the past week is the 3D printed brushless gimble.

Those over at Hackaday and had 2 posts about this today and yesterday, aswell as discussion on Reprap forum, but it is a very interesting idea.

http://hackaday.com/2013/06/17/brushless-motor-camera-gimbal/

http://hackaday.com/2013/06/18/brushless-gimbal-3d-printed-and-bolted-to-quadcopter/

I own a quadcopter, although my flying times are small, i have had it in the air with my HTC desire S strapped to it to get some rather shakey camera footage.

Im thinking, i ahve accelerometers, spare brushless motors, spare brushless controllers and a quadcopter, not to mention FPV equipment! oh and 3d Printer…

Im thinking this is worth while to build one of these!

Should also make this… http://www.thingiverse.com/thing:76369

Additional:

Gimbal controller

After further investigations i have found the controller is a board from Flyduino and costs $110, so i think i may have to wait for costs to decrease first!

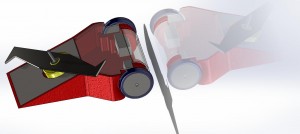

Antweight robot design V3

Hi all, just thought i would show you the latest in design of my Ant, name to be decieded, but will be a goodan, i have some possibilities, just need to check if there not taken!

This is a mock up design in solidworks, but i also have it printed and fited.

I have a controller design ready and now i have the design as i like i can start to design the PCB and get aluminium for the chasis walls 🙂

Let me know what you think

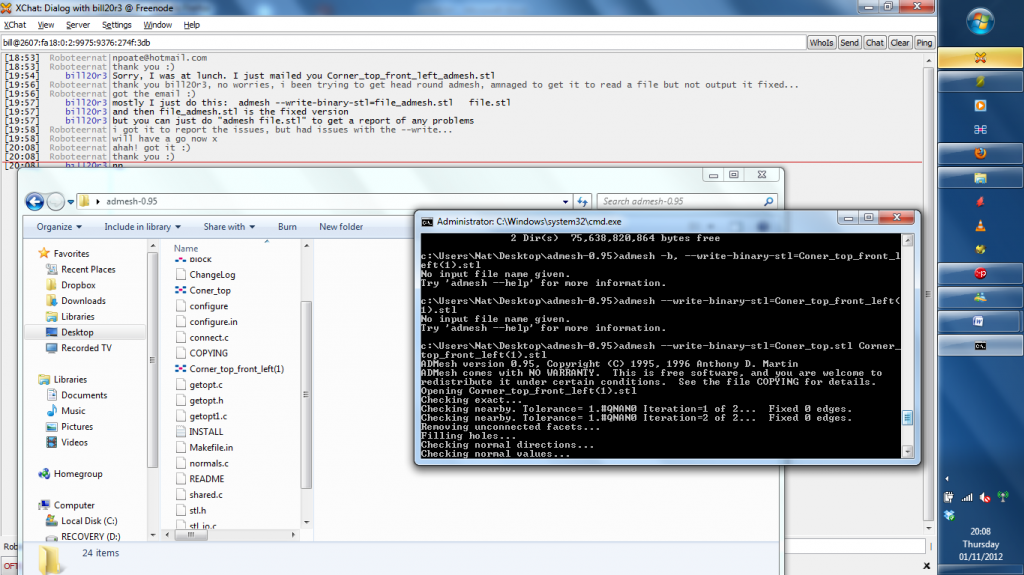

Admesh program to fix broken STL files

I attempted to open the tantillus stl file for top corner front left but sadly it failed in lic3r saying it had no slices or something, and Bill20r3 and teepee on IRC #Reprap explained about Admesh program.

A commad bassed programme, it fixes / translates rotates etc stl files.

to download:

bill20r3> admesh seems to have fixed it just fine, fwiw.

admesh?

admesh is an open source program for repairing, translating and processing STL meshes. It’s very fast and almost as old as 3D printing. https://sites.google.com/a/varlog.com/www/admesh-htm

if this is down due to server issues go to:

http://ftp.de.debian.org/debian/pool/main/a/admesh/

and download

admesh_0.95.orig.tar.gz 12-Oct-1998 20:52 50K file.

Roboteernat: bottom of the page https://sites.google.com/a/varlog.com/www/admesh-htm – the small arrow pointing down

download the file and save to desktop.

open command prompt window and change directory to point to admesh folder

save the broken stl file needed t be fixed ithin the admesh folder and confirm it id there by using cmd window and typing 'dir' to list the files in the directory

Once it is there, we can fx it.

Type

admesh --write-binary-stl=file_admesh.stl file.stl

where file_admesh.stl is the file output name

and file.stl is the name of the file to be fixed

Here is an example print screened for the future 🙂

the file ‘Corner_top_front_left(1).stl has been fixed and saved as Top_corner.stl in the admesh folder.

All slicing fine now 😀

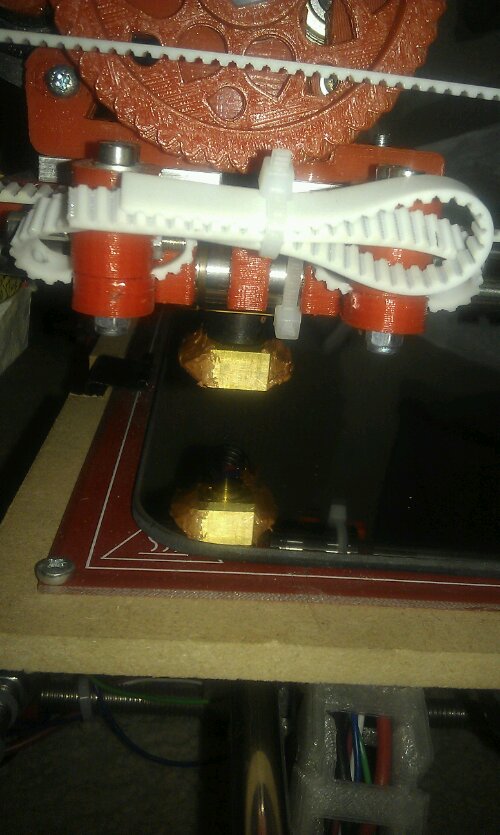

Replacement extruder head

New extruder fitted, j-head away it goes! My old ptfe extruder head finally split, will see if I can remake it using PEEK

New ahead extruder fitted

Printed base for sang board

And for fun…

Heatbed heaters… using hair straightners

Well, since march, i been loking at making my own heat bed for my huxley.

Speaking online last night to reprappers on irc, i came up with the idea of using PTC heaters as a heating element for the heatbed. I saw these: which are available in 30v (powered from 12v) and 200watt versions.

Researching into these, it turns out that PTC heaters are used in Hair straightners too!

I looked in my local shop and the cheapest was £4.99 but these were not variable heating, these were £20 onwards. The veariable ones would be required, as these can go down as low as 40degrees C.

I decieded to try and get some second hand ones as the cost for a new one, that i could potentially break, as a bit outweighted.

The local Carboot sale prooved fruitfull. The 50p box at one stall revealed many electrical items including 4 sets of variable hair straightners.

The models i got are:

Remmington S-8200 (85 Watts)

Superdrugs own brand MCS3701/405965 (160 Watts)

KODO (cheap n nasty) KO300V (65 Watts)

Tony and Guy TG094 (Straightner adapter) (24-70Watts)

The first 2 are aluminium plates and the other 2 are ceramics.

The Tony and guy model features an LCD display!

All are variable and low on one model shows 60 degrees celcius! prfect for PLA

There are a few features that are a bit annoying… all have 60minute auto off! this should be bipassed by using a relay connected to the on/off switch and controlled through the mosfet on the electronics board. These are all 240 volt models and therefore could be VERY dangerous! Im using a RCD device when testing these, and hopefully i will still be living enough to finish this post 😀

The KODO model

These by far look the cheapest, and the connector for the mains plug feels a bit gritty, so i will take these apart first f all.

The heaters which seem to be in heair straightners are PTC which is ‘Positive

Temperature Coefficient’ information can be found in more detail via http://www.dbk-usa.com/ptc-heaters

“Positive Temperature Coefficient (PTC) heating elements are small ceramic stones with self-limiting temperature characteristics. PTC stones have fast heating response times and plateau once the pre-defined reference temperature is reached. It is possible to form the stones into a square, rectangular, circular or ring shape. Above the reference temperature, the semiconducting and ferro-electrical properties of the ceramic are utilized to produce a rise in resistance of several orders of magnitude, and thereby creating it’s self-limiting properties”

from

So, peltier stones ay? lets see what these look like…

Taking apart the KODO heater, it is obvious why cheap hair straightners break, the wires are thin!

The circuit board seems to feature AC input into a TRIAC http://www.datasheetcatalog.org/datasheet/stmicroelectronics/8666.pdf BTB04-600SL The heater wires connect to one power side, then then the TRIAC.

The temperature wires – i assume a thermistor like we use on repraps, connects to power and a small chip, PM3/8U? which i assume is a microcontroller.

The heater elements look as if it is clamped into the ceramic housing, this is to force contact onto the ceramic plate.

The heating element is actually loose and taped together using polyimide tape but features 2 power plates and 2 ceramic Peltier? blocks, all sandwiched together.

The fact these are loose means that this is a very cheaply made unit, and the ones on farnell seem to be housed inside an alumninium block.

Eitherway, if i were to use these i will have to force contact.

The remington straightners.

These are aluminium plates and could be very easy to bolt to an aluminium plate.

Again a small circuit board, with a TRIAC and variable resistor.

The aluminium plates also seem to have loose PTC elements (this time taped togeter in more kapton tape, but a much larger plate!

The superdrug straightners.

OOh a nice WADE spring!

Again, the heating plate is made up of 2 plates and some ceramic plates inside,

but this time the plates are mecahincally clamped in

Well, its been a while

Hi folks, whats new?

Well its been a few months since my last post, and i been needing to update things.

Basically i am creating the Huxley MD (My Design) reprap machine with my machine, and also started to make a stepper struder for my makerbot – running mk5!

so there has been lots to talk about.

After heading to the makerfaire in nottingham, i spoke to jeanmarc of emaker shop, and saw the small huxley he was making, i liked it, and wanted to make it. I didnt like the design for the extruder, and i wanted a more recognisable extruder that has been used, therefore i wanted to use the makergear hot end.

Also i wanted to use different bearings, lm6uu for 6mm rods.

I designed the parts and a picture will be put here, but there are flickr pictures!

I also have bought some angel eyes from ebay to fit onto my makerbot and reprap – 90mm and 50mm diameter lights! VERY nice and a recommendation to all!

The makerbot has been upgraded to feature a stepper motor, and im waiting for the gen 4 stepper motorfrom makerbot to fit onto it and make it amazing 🙂

Looking at stewarts build, the stepper motor design makes FAR better quality prints!

anyways, im also trying to design a heat bed for the huxley 140mm by 140mm so that Jeanmarc can use them on his emakers he is selling, and i can have one for myself!

sadly the etch tank has become too full of copper, and therefore i need to dispose of it and start with a fresh ammount of acid. This is a complex process involving taking the chemical to a hazardous waste recycling facility! and costs!

anyways, thats a brief summary of whats been going on. Oh and i got woodworm in my room, so im hoping its not going to the makerbot!!!

Blue magic smoke :(

So, here it is… as im designing a shell for use in a project, which needs to be completed by Wednesday… for the MCM expo! Yes the MCM expo in london next weekend, i go to use my makerbot, and sadly the Z axis starts playing up… then a wiff, snap crackle and pop (and no mini cartoon characters to see for miles) the stepper motor controller decieds to frazzle.

Luckily when the first time this happened, i ordered 2 spare chips, so i can replace the chip, will just take time…

Here goes!

Building of wobble arrester and new cable

Well its been an eventfull couple of weeks.

firtly i decieded to change my usb ttl adapter for the makerbot to a 5v logic level, as apposed tothe 3.3v logic level one i was using. the idea behind this was that the switchover signal voltage could have been too low and therefore meant the data was not being sent at good quality. I was annoyed when i bought the first cable, as i was thinking it was a 5v level cable, but alas… oh well.

the first tests came as i was setting up the uni makerbot for a demo of high calibre… more on that in a sec, but i managed to start repg and the new software version, meaning i could import and manipulate the files stl etc in repg.

the first trial pieces were done using my pc desktop, an old pentium 4. (i now bought a i5 HP laptop, so yay!) I did wounder if the processing speed was too slow for the makerbot, and i think i might have been right…

anyway, my first prints using the 5v cable, turned out to be good. they were a corner bracket, to try simple shapes… and then the z wobble arrester. this is an amazing thing an im glad i printed it, as my sides are virtually wobble free (need a second one for other side of rear as that too is a bit wobbly…

anyhow, i printed these with great success, installed the wob arr and set to print something more complex. The gear set, recently uploaded seemd lie the perfetc vhoice.

link here :(insert link)

the results seemed ok, but the thinner smaller gear had to be height adjusted as too much plastic was comming out causing lumps. – this maybe because there wasnt enough time to cool befre the heater nozel came ploughing through, so need to work on ‘cool’ settings as mentioned in recent blog post elsewhere – should really write the links down!. need to adjust speed and extruder flow rate too, both adjust this issue.

right a picture…

or 2…

the L bracket, shows several wobbly edges so off to print the z wobble arrester…

the wobble arrested whilst printing

The wobble arrester works wonders, and if anyone needs to see why it is handy, check this video out of the one i installed…

with the wobble arrester installed, i made the gears.

picture too come.