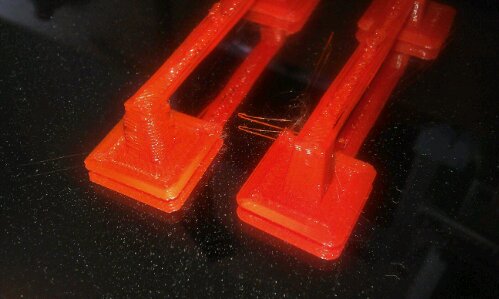

So, a project of mine requires me to screw a lid into a 3d printed chasis, and make it secure!

The mnost common thing to do is to just drill and tap into the plastic part to give it the screw thread in which to screw into.

There are several issues, A its weak. drilling into an object with a low infill ratio will mean there is no material around after you have drilled into the first few top layers meaning it only will give 1 thread. Not much!

To overcome this, you can up the fill, or print a hole inwhich to tap, and give it additional perimeters so it makes it solid around the thread. again this is better,but we rely on plastic threads to grip into.

Lets take a look at those examples used in industry. Thermal injection to be precise.

When putting a thread into a plastic part, the best way is to add a brass threaded insert. These are small threaded nuts with a grippy outside which is placed into a mould tool before plastic infection. They remain fitted to the plastic due to the burrs on the outside edge, but give a brass heavy duty thread on the inside.

These are cheap, well about £50 for 100, 50p each is the cheapest through a company, ebay sell 100 for about £13.50?

These are used ofetn for parts, including the plastic/glass fibre arms for my quadcopter.

When it comes to 3D printing, we are unable to print around these inserts, therefore another insertion method is needed.

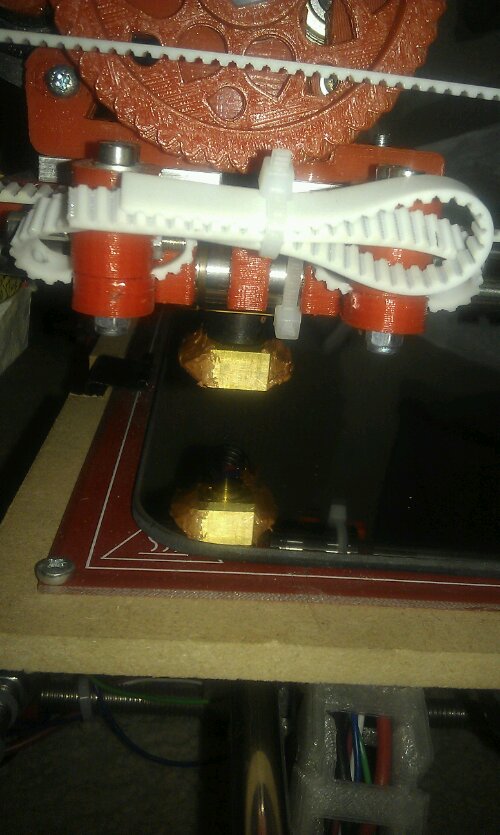

Firstly we need to print a hole for the brass insert to fit into. This gives the surrounding purchasing for the fitting to fit into.

Then we place an insert onto the tip of a soldering iron, so the iron heats the insert.

Then using the iron, push the brass insert into the plastic hole, so the plastic melts around the insert.

Removing the soldering iron allows the insert and plastic to cool, leaving you with a brass insert thermally welded into your plastic part.

I just need to get hold of some thermal inserts!

Check out this video for more info…

Hole size recommendations pdf is available here: http://www.axisproto.com/pdf/spec_inserts_EN.pdf