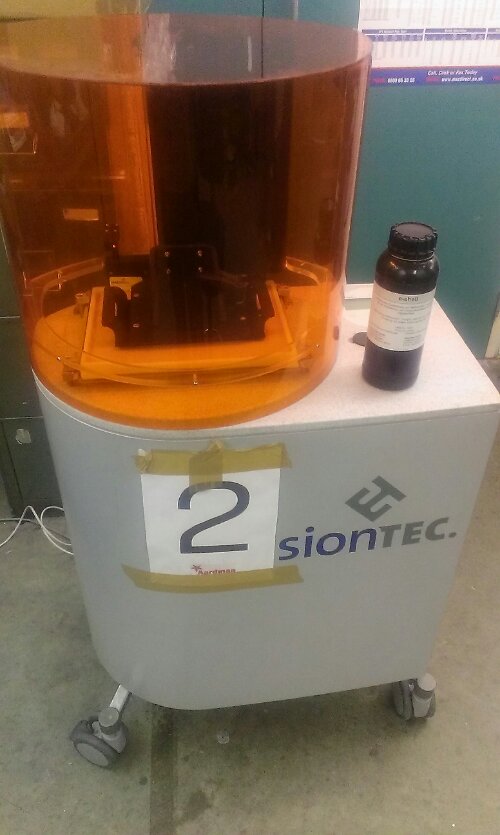

So setting of the 3d printer we had two models 1 was a dodecahedron, the other was a spare, the dodecahedron was a model that contain another dodecahedron inside each other suspended in mid air. This was unknown at the time however. Adding both files to the magics software and creating a job to import into perfactory 3D we got the machine off running using pink material.

Here you can see about 10 millimetres of the model has been printed and is sticking out of the vat of resin. This is about an hour into the print the total print time is 4 hours.

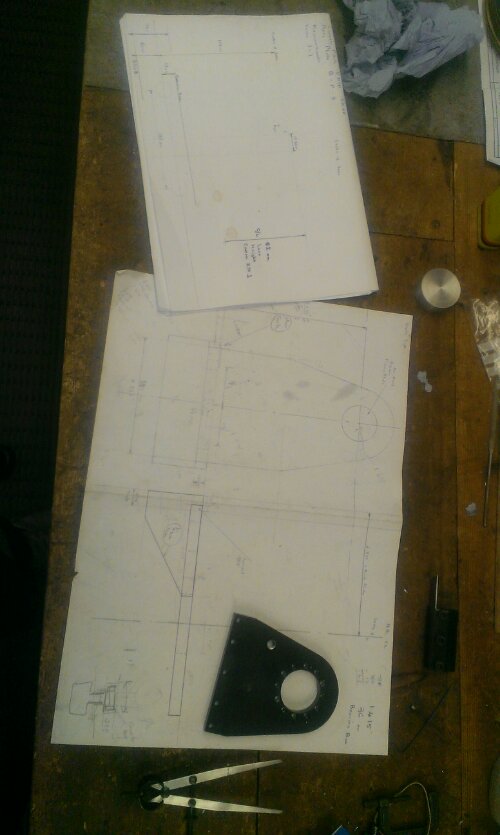

This picture you can see the dodecahedron peeking out the bottom there is no dodecahedron that he done inside this is because the model was constructed without support material meaning of the internal parts will not supported . This means the currently the central internal model resting inside may be picked up later on during the print process later today. However although this part will be a failure the sphere is turning out nicely which should resulting in a clean sphere. We have to wait another 3 hours to see the final outcome.

(note post was spoken and reedited so may seem a bit odd reading)

Posted from WordPress for Android