So, after a few months at Aardman, I have accumulated a number of end mills, which are rolling about the tray, which… is not the best, as any slight nick on the cutting edges can result in ugly surfaces – yes end mills are to cut side on! not really for plunging at ends, but we all do that anyway!

So I have about 12 or 10 cutters which I have tried to restrain usingcloths, wooden disks etc but each time the drawer is opened and closed they rattle loose…

So, I decieded to mill out a ‘cutlery drawer’ style thing for them, you know the ones with slots to hold knives, forks, spoons, and that garlic crushed insert full of bits of old garlic that the spikey brush just can’t remove… Anyways you know.

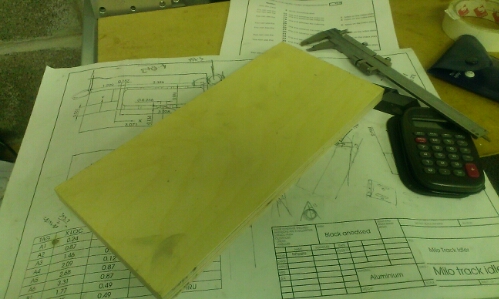

So I got a bit of plywood 3/4inch thick, and roughly draw a few marks on it in the shape of slots that could hold my cutters, just to give an idea.

I wanted a selection of sizes of slots so I picked the medium sized cutter I had, I think that was 5/8th or 3/4, tho I think it was the first, I clamped down the plywood and set up the cutter at the first roughly drawn slot.

Powering on the milling machine I made my fiirst cut to a depth of 350 thousandths and cut a series of slots, I got 6 slots horizontal about 3inches long which fitted my smaller cutters.

The next set of slots are made wider by running the cutter offset from the first slot, again leaving a small edge between slots, this gave me again 6 slots by starting closer to the edges.

The final 3rd of wood is made into longer wider vertical slots to house 1 inch and 3/4 cutters, 3 slots are given. All this milling creates a lot of sawdust… time for a vacuuming!

Removing the wood from the machine revealed lots of splinters on the edges of the top of the slots. A bit of sanding down and all done!

Large cutter doesn’t fit! Oh no! So a quick chiseling….

All done! Tidy drawers!

Pingback: Hackaday Links: May 18, 2014

Pingback: rndm(mod) » Hackaday Links: May 18, 2014

Pingback: Hackaday Links: May 18, 2014 - RaspberryPiBoards

Pingback: Hackaday Links: May 18, 2014 - Tech key | Techzone | Tech data

Pingback: Hackaday Links: May 18, 2014 | Hack The Planet