I have been machining and selling drill motor mounts now for several years for the robotic community, and i am now able to offer the following services:

CNC Milling

CNC Routing – plastics, metal and composites.

3D Printing

3D Design

Sale of screw and play drive systems for robot combat

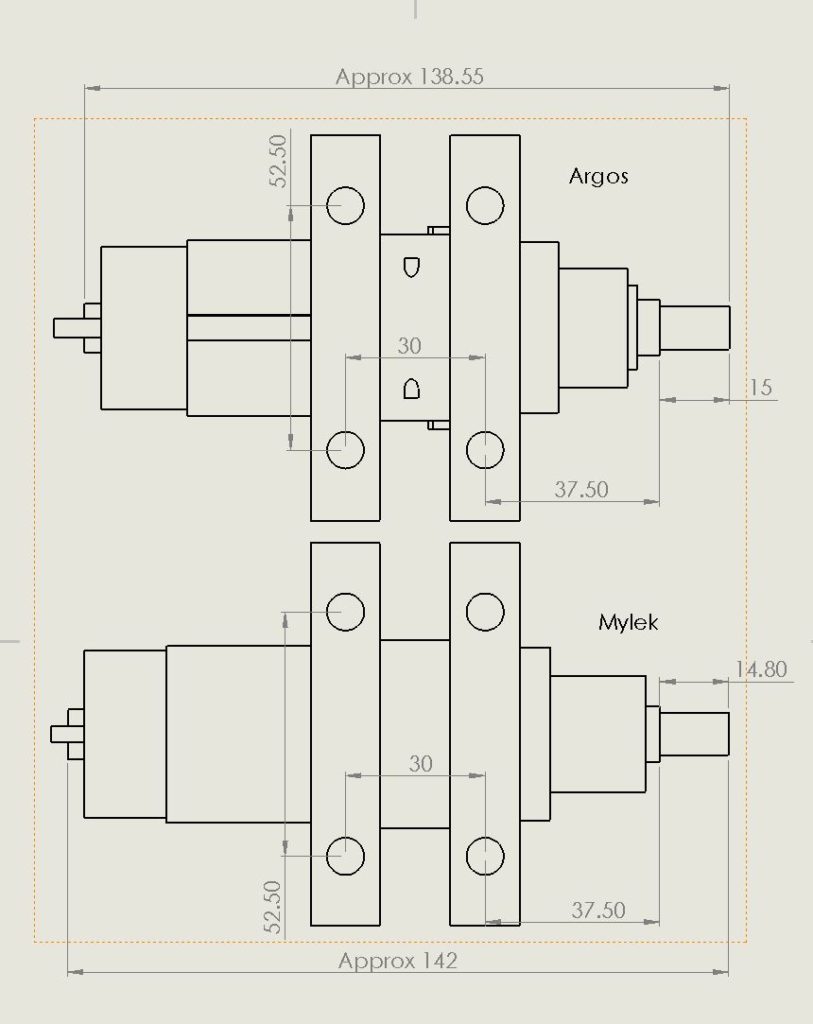

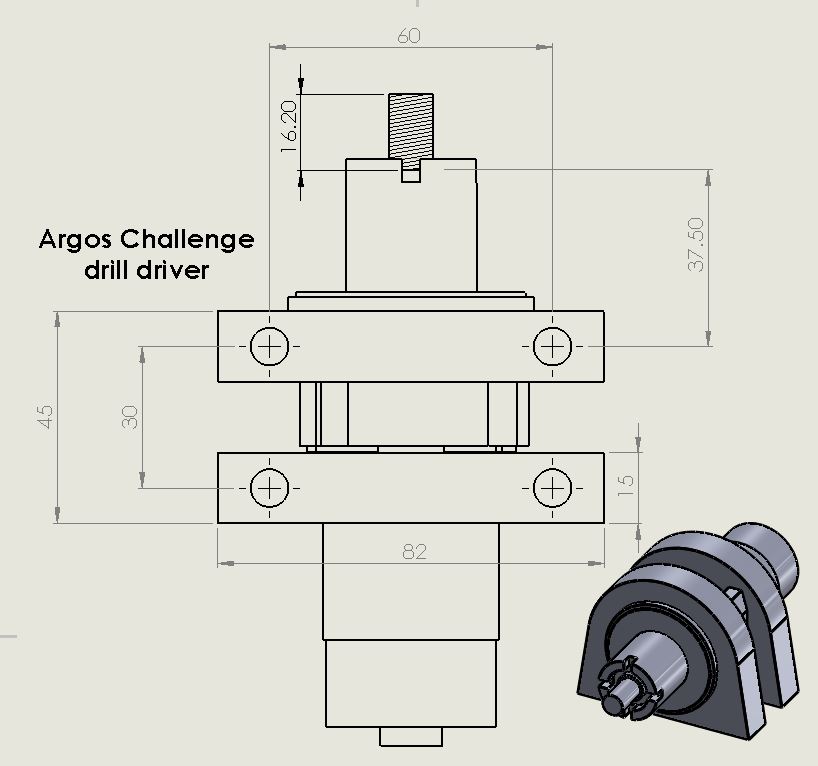

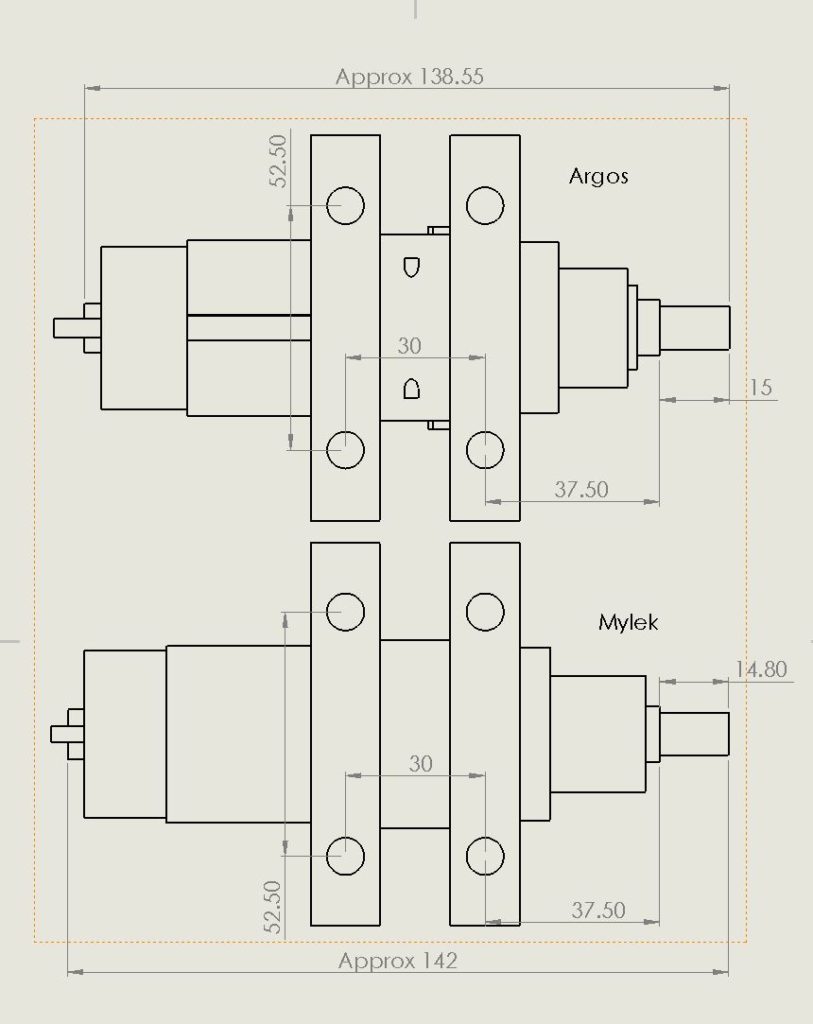

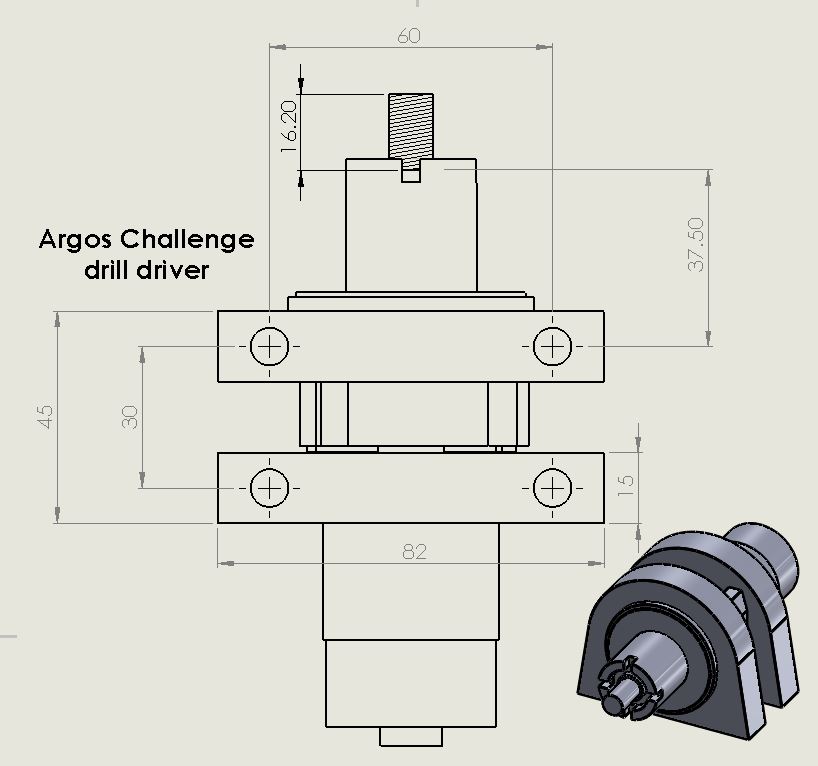

The drills I currently have designed mounts for are:

Mylek

Black and decker

Argos (old design – now discontinued drill by Argos)

Argos Challenger

Argos Guild

Bosch PSR (and another?)

Vonhaus 18v drill in development for mid August

If you have another drill in mind, I welcome being sent the drill so i can make a mount for you, or if you want the mount to be added to a custom panel i can machine that too.

I also make drive systems ready to attach to your drill. Including wheel hubs, machined nylon wheels and fitting of bike tyres.

I also machine weapon pulleys for spinning blades. I can machine your parts from aluminium, or design complete robots for you.

Please message me for more information or to discuss your requirements.

npoate@ hotmail . com or contact me on FRA forums – Roboteernat https://www.fightingrobots.co.uk/members/1240-roboteernat